bit-tech: Briefly describe how you actually go about making a case using carbon fibre?

Dave: A fair warning to all: give a lot of forethought in design before attempting carbon fibre construction. Let's do a compare and contrast! Square Box case vs. SSR-X. The first place to start is the design of your case and the carbon fibre production process that you would like to use. Also along with this what type of final finish would you like your carbon fibre to have.

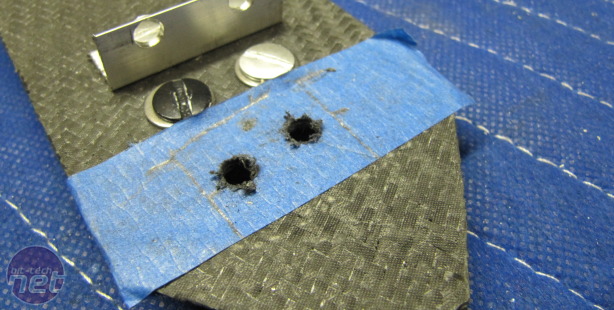

In the case of a square box the open air lamination method would produce a quick and cheap result if you are looking for speed and simplicity in design. All one would need is a flat piece of metal to make the laminated sheets of carbon fibre. I would recommend resin infusion over vacuum bagging because with the same flat sheet of metal an infusion could be done to produce a high quality gloss finish part. Infusion requires flanges on the mould piece you are using. Whether it is a flat piece of metal or a mould like SSR-X.

To contrast the case of a square box when your design has curves or is geometrically continuous in shape, a mould is required. Your design is crucial now! Your design may call for flanges and a certain shape mould to be created to make your carbon fibre part. Likewise, your design may let you create a simple mould. Design, design, design! From there, depending on your production process, will determine the amount of time and money you will have to spend, along with quality. The bigger and more intricate the mould the more time and money will have to be spent.

Finally when your carbon fibre parts and pieces are made than it's just bolts, screwing, or gluing the pieces together to make the final case. One may additionally put in aluminium and acrylic pieces in the build like SSR-X.

bit-tech: Is it just as easy to make small objects as it is large ones?

Dave: Here large parts just mean more expense. Depending on the design of the part again will determine whether it is easy to create or not.

bit-tech: It is easy to create fine details?

Dave In my limited experience, I would have to say that fine details can be captured as long as they are larger enough in recess to let the fabric into that recess. Carbon fibre tucks into tight places really well. What you will get is weave distortion and some people don't like that.

bit-tech: Overall what’s been your impression of it when you used it with SSR-X?

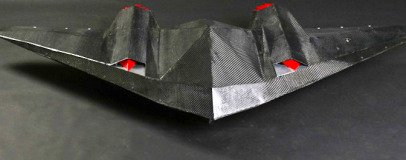

Dave: In the end, if SSR-X were all aluminium or steel it would be an inefficient build from a standpoint of weight. It would be too heavy for one person to move around. The use of composites, i.e. Carbon fibre, was essential to making this build efficient. The true carbon fibre look gives SSR-X the stance that I wanted from not only a viewer's stand point but a photography standpoint as well. I couldn't imagine SSR-X now without it being carbon fibre. In my eyes, SSR-X turned out great for such a complex build.

A huge thanks to Dave for talking to us and we can't wait to see his full SSR-X article here on bit-tech. What do you think about using carbon fibre in PC modding? Have you used any other exotic materials? Let us know in the forum.

Dave: A fair warning to all: give a lot of forethought in design before attempting carbon fibre construction. Let's do a compare and contrast! Square Box case vs. SSR-X. The first place to start is the design of your case and the carbon fibre production process that you would like to use. Also along with this what type of final finish would you like your carbon fibre to have.

Click to enlarge

In the case of a square box the open air lamination method would produce a quick and cheap result if you are looking for speed and simplicity in design. All one would need is a flat piece of metal to make the laminated sheets of carbon fibre. I would recommend resin infusion over vacuum bagging because with the same flat sheet of metal an infusion could be done to produce a high quality gloss finish part. Infusion requires flanges on the mould piece you are using. Whether it is a flat piece of metal or a mould like SSR-X.

To contrast the case of a square box when your design has curves or is geometrically continuous in shape, a mould is required. Your design is crucial now! Your design may call for flanges and a certain shape mould to be created to make your carbon fibre part. Likewise, your design may let you create a simple mould. Design, design, design! From there, depending on your production process, will determine the amount of time and money you will have to spend, along with quality. The bigger and more intricate the mould the more time and money will have to be spent.

Click to enlarge

Finally when your carbon fibre parts and pieces are made than it's just bolts, screwing, or gluing the pieces together to make the final case. One may additionally put in aluminium and acrylic pieces in the build like SSR-X.

bit-tech: Is it just as easy to make small objects as it is large ones?

Dave: Here large parts just mean more expense. Depending on the design of the part again will determine whether it is easy to create or not.

bit-tech: It is easy to create fine details?

Dave In my limited experience, I would have to say that fine details can be captured as long as they are larger enough in recess to let the fabric into that recess. Carbon fibre tucks into tight places really well. What you will get is weave distortion and some people don't like that.

bit-tech: Overall what’s been your impression of it when you used it with SSR-X?

Dave: In the end, if SSR-X were all aluminium or steel it would be an inefficient build from a standpoint of weight. It would be too heavy for one person to move around. The use of composites, i.e. Carbon fibre, was essential to making this build efficient. The true carbon fibre look gives SSR-X the stance that I wanted from not only a viewer's stand point but a photography standpoint as well. I couldn't imagine SSR-X now without it being carbon fibre. In my eyes, SSR-X turned out great for such a complex build.

A huge thanks to Dave for talking to us and we can't wait to see his full SSR-X article here on bit-tech. What do you think about using carbon fibre in PC modding? Have you used any other exotic materials? Let us know in the forum.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.